How To Choose An Injection Molding Machine?

How to choose an injection molding machine?

The purchase of an injection molding machine is not a small investment. It is a waste to buy an injection molding machine that is too large, and it is not suitable to buy an injection molding machine that is too small. Therefore, choosing an injection molding machine that meets the customer's own product needs has become the most concerned content of every buyer.

When selecting an injection molding machine, the standard for selecting a machine based on the injection weight alone is oversimplification, and it is unreasonable to use only the clamping force. Therefore, we must combine the two and make a reasonable choice.

1. Determination of the injection weight of the injection molding machine

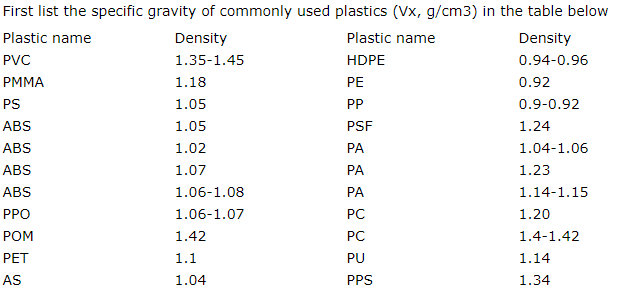

The injection weight is an important parameter of the injection device of the injection molding machine. It is the most commonly used parameter and also the key parameter when choosing an injection molding machine. Expressed in grams (g) or ounces (oz) (Note: 1g=0.035 ounces, 1 ounce=28.35g) Although this parameter is simple and clear, it is also easy to be misunderstood. In fact, the definition of injection weight refers to the maximum plastic injection weight that the injection device can reach when the injection screw is used as a maximum injection stroke under the condition of air injection (without injection into the mold); this parameter is to a certain extent Reflects the processing capacity of the injection molding machine; it can be measured or calculated from theory. (There will be a certain degree of difference between the theoretical value and the measured value.) The rubber used in the test is usually a general PS hard rubber with a specific gravity of 1.05.

Steps to determine the injection volume:

1. First calculate the weight of the product: w = product weight + gate system weight (weight required for W injection)

2. When the injection molded product is polystyrene (ps), the injection volume of the injection molding machine should be WPS; Wps=(1.3-1.1)*W (product weight + total gate system weight), where the quality of the product When the requirement is high, the coefficient should be a large value, otherwise it can be a small value.

3. When the product is other plastic (named X plastic) according to the above method, first calculate the theoretical injection volume of the plastic that should be Wx; Wx=(1.3-1.1)*(product weight + total gate system weight ); Then according to the density of the plastic (X) converted into the actual weight of the PS material Wps, the conversion formula is WPS=Wx*1.05/VX

4. According to the calculation result Wps and the product sample comparison, select the appropriate injection molding machine

2. Calculation of clamping force of injection molding machine

There are two important factors for calculating the clamping force: 1. Projection area 2. Cavity pressure

1. The projected area (S) is the largest area viewed along the opening and closing of the mold.

2. Determination of cavity pressure (P)

The cavity pressure is affected by the following factors

1. Number and location of gates

2. Gate size

3. The wall thickness of the product

4. The viscosity characteristics of the plastic used

5. Injection spee